- Overview

- Product Description

- Product Features

- Product Parameters

- Our Main Products:

- Company Profile

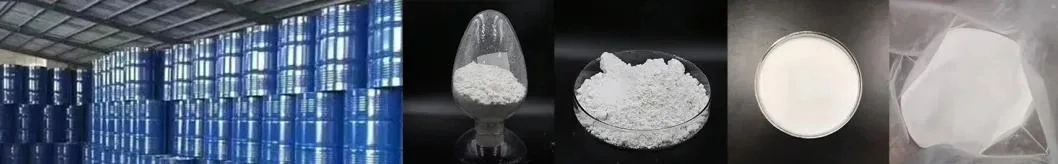

- Packaging & Shipping

Basic Info.

Product Description

HAIFLON® PTFE medium-size particle resin

CAS No.:9002-84-0Description

Haiflon® SG-208 and SG-218 are PTFE semi-flow Resin. They are virgin white powder with medium particle size, and designed to produce PTFE big billets, rod, sheet, tube, film and other sealing materials etc. PTFE Semi-flow has bigger particle size, medium bulk density and better flow ability than PTFE low-flow. PTFE SG-208 and SG-218 could also be used to produce different kinds of PTFE compounds, Presintered PTFE and PTFE free flow etc.

☆ PTFE semi-flow resin

☆ Good electrical and mechanical property

☆ Medium bulk density and good flow ability

☆ Excellent chemical resistance

☆ Suitable for molding process

| SG-208 | SG-218 | |

| Appearance | White powder, no impurities | White powder, no impurities |

| Tensile strength, Mpa ≥ | 25.5 | 25.5 |

| Elongation at break, %≥ | 250 | 250 |

| Bulk density, g/L | 500±100 | 500±100 |

| Average size, d50 µ m | 60-100 | 100-260 |

| Moisture, % ≤ | 0.03 | 0.03 |

| Melting point, °C | 327±5 | 327±5 |

| Standard relative density | 2.13-2.18 | 2.13-2.18 |

| Thermal Instability Index, ≤ | 50 | 50 |

| Electric intensity, MV/m ≥ | 60 | 60 |

| Product characters: | The partial size is uniform, suitable for skived molding big plate and turning film. SG-208 can replace some products of molding powder, and has good brightness in the appearance | The partial size is uniform, suitable for skived molding big plate and turning film. |

| Application | Make tube, rod, plate and seal material, etc. | Make tube, rod, plate and seal material, etc. |

https://haiflon.en.made-in-china.com/contact-info.html

https://haiflon.en.made-in-china.com/contact-info.html

https://haiflon.en.made-in-china.com/product-list-1.html

Shanghai FluoroChem Industry Co., Ltd. is a tech enterprise specialized in development, production, sale and service of fluoropolymer & Fluoroelastomer. Our R&D team composed of chemical doctors and professors, we have strong technical strength and rich experiences in fluor-ine chemistry field.

Our goal is develop the environmental protection type, fluori-ne containing new material; Our Mission is providing customers with best support for product and research; Our service tenet is help the customers get the best products and the benefit by our advanced technology and first-class professional knowledge. No matter where you, no matter how complex your application is, we will try our best to provide you the best service.

Our products have been widely applied to wires & cables, pipes, coating for metal, film, seal tape, valve lining, waterproof coating of welding electrode and many other fields, widely adopted by many domestic and foreign manufacturers. Presently, our products are divided into six major categories, more than dozen of models, including PTFE, PVDF, FEP, FKM, PTFE Micropowder, PPA, Fluor-ine-containing fine chemicals etc.

We have warmhearted staff and strong ability of research and development, we promise the rapid response to customer's demand, provide high quality products and services, share the success with customers.

In order to provide you with high quality products and technical services, and improve the quality of our products constantly, we make the following commitments hereby; Please pay your supervision on our products and services.

-->Product quality

All products can be provided detection report information by the authority organization in strict accordance with national targets.

-->Service requirements

To ensure that customers understand the product structure, performance, and characteristic through various ways before ordering, help customers choose the right products, and make improvement continuously.

-->Service goals

Make customers satisfied and rest assured, serve customers whole-heartedly, improve service quality ceaselessly.

-->Service commitment

Professional service with good faith, good quality with low price, we certify to solve problems for customers and improve our product quality.

Packing, Storage & Transportation

- Packed with sealed PVC bag, load in Melting peak temperature proof paper barrel. The net weight is (25±0.1) kg per barrel.

- Not classified as hazardous for transport. During transportation and storage, avoid heavy shaking, and prevent from heating. It is better to load in refrigerator during transportation.

- It should stock in clean, cool and dry warehouse, prevent from agglomeration and contamination.